PTFE=Polytetrafluoroethylene

UHMW-PE=(Utra High Molecular Weight Polyethylene)

HG=Phenolic Resin with Fabric Reinforcement

With the PTFE materials it must be taken into account that the permissible surface pressure decreases with increasing temperatures. The load bearing ability for dynamic applications in practice is dependent primarily on the operating temperature. This should therefore generally not exceed 150°C. For temperatures below 0°C

consult technical support.

The linear length of DL GST is calculated such that a gap “Z” is created at the ends of the strip after installation.

This is required for the following reasons:

-Compensation of the linear expansion of the strips due to the effects of temperature

-Avoidance of intermediate pressures and entrained Pressures.

Forms of Supply

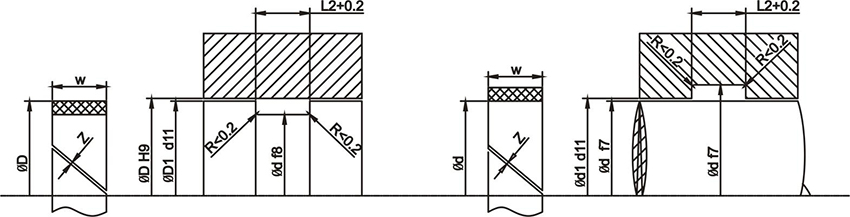

Two characteristics must be observed with respect to the forms of supply forDL

GST.

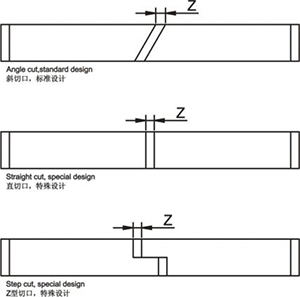

-Type of cut

The Angle Cut is the most frequently used standard type of cut. Rings with other

types of cut – Straight Cut and Step Cut are available on request.

-Design type

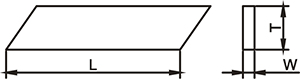

DL GST has a rectangular cross-section with rounded or chamfered edges, thus

preventing impermissible edge forces in the corner radii of the grooves.The

chamfers also serve to facilitate installation, e.g. when inserting into the cylindrical

tube or guide bush.

The ring ends are finished as standard with an angle cut.

Strip material is available in rolls or precut to size to fit with the gap necessary.

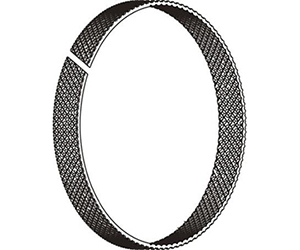

Empaistic structure

GST up to and including 2 mm radial thickness in PTFE materials are as standard

supplied with Empaistic structure on the sliding surfaces.

This structure comprises small lubricant pockets on the surface which improve

the initial lubrication and promote the formation of a lubricant film. They also

help to protect the seal system through their ability to embed any foreign particles.

In order to be able to use the strip material for both piston and piston rod guides,

the rings have this same empaistic structure on both sides.

|

|

| 120° C |

| 120° C |

When ordering strips off-the-roll for manufacturing of DL GST in your own works,

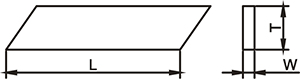

the length of the strip can be calculated using the following formulae:

For Piston:L=cx(D-W)-k[mm]

For Rod:L = c x (d + W) - k [mm]

D=Bore diameter [mm]

d=Rod diameter [mm]

W=Ring thickness [mm]

c = 3.11 material factor

k=0.8 for operating temperatures up to 120° C.

k=2.0 only for applications > 120° C.

Length of per PTFE Strip Roll

| Thickness |

1 |

1.5 |

2 |

2.5 |

3 |

4 |

5 |

6 |

| Length of Roll (M) |

55 |

35 |

27 |

22 |

18 |

13 |

10 |

8 |

*For Reference only. There may have minimum difference.

Order Example for standard version:

Groove Width L2= 20 mm; Ring Thickness W=2.5 mm; Material = PTFE, Order in roll

L2=20mm,W=2.5mm, PTFE,Order Code GST 20 x 2.5

For special design such as Empaistic structure, Chamfer edge, Split ring, Special material and/or cut type, please indicate.

Suitable for Groove Width

Further sizes are available

| Groove Width L2 |

2.5 |

3.2 |

4 |

4.2 |

5.6 |

6 |

6.3 |

8.1 |

9.7 |

10 |

12 |

15 |

20 |

25 |

30 |

40 |

50 |

Available Ring Thickness

| Ring Thickness W |

1 |

1.5 |

1.55 |

2 |

2.5 |

3 |

4 |

5 |

6 |

Further sizes are available

Each customer has a quality file, which is tracked regularly. The customer feedback problem, the fastest 1 hour to give the customer satisfaction solution.

Each customer has a quality file, which is tracked regularly. The customer feedback problem, the fastest 1 hour to give the customer satisfaction solution.